When it comes to DC motor speed control, choosing the right type of drive can significantly impact performance, efficiency, and application compatibility. Two of the most common types of DC motor controllers are SCR (Silicon-Controlled Rectifier) drives and PWM (Pulse Width Modulation) drives.

In this article, we’ll explore the key differences between PWM vs SCR drives, including how they work, where they’re best used, and which type might be right for your system.

🔧 How SCR Drives Work

SCR (Silicon-Controlled Rectifier) drives are phase-controlled rectifiers that regulate motor voltage by controlling the phase angle of the AC input. As the firing angle of the SCRs changes, the average DC output voltage to the motor adjusts accordingly.

✅ Advantages of SCR Drives

- Ideal for higher horsepower applications

- Compatible with 90–180VDC motors

- Capable of regenerative braking (in 4-quadrant models)

- Rugged and reliable in industrial environments

🔻 Limitations

- Not suitable for battery-powered systems

- Creates electrical noise and waveform distortion

- Larger and heavier due to heat management needs

⚙️ How PWM Drives Work

PWM (Pulse Width Modulation) drives regulate motor speed by rapidly switching the DC voltage on and off, controlling the average voltage and current the motor receives. This technique is much more efficient and is ideal for low voltage applications such as 12VDC and 24VDC systems.

✅ Advantages of PWM Drives

- High energy efficiency

- Compact and lightweight

- Ideal for battery-powered systems and mobile equipment

- Generates less heat and quieter motor operation

🔻 Limitations

- Not suitable for high-voltage or high-current industrial setups

- May require shielding or filtering in sensitive environments

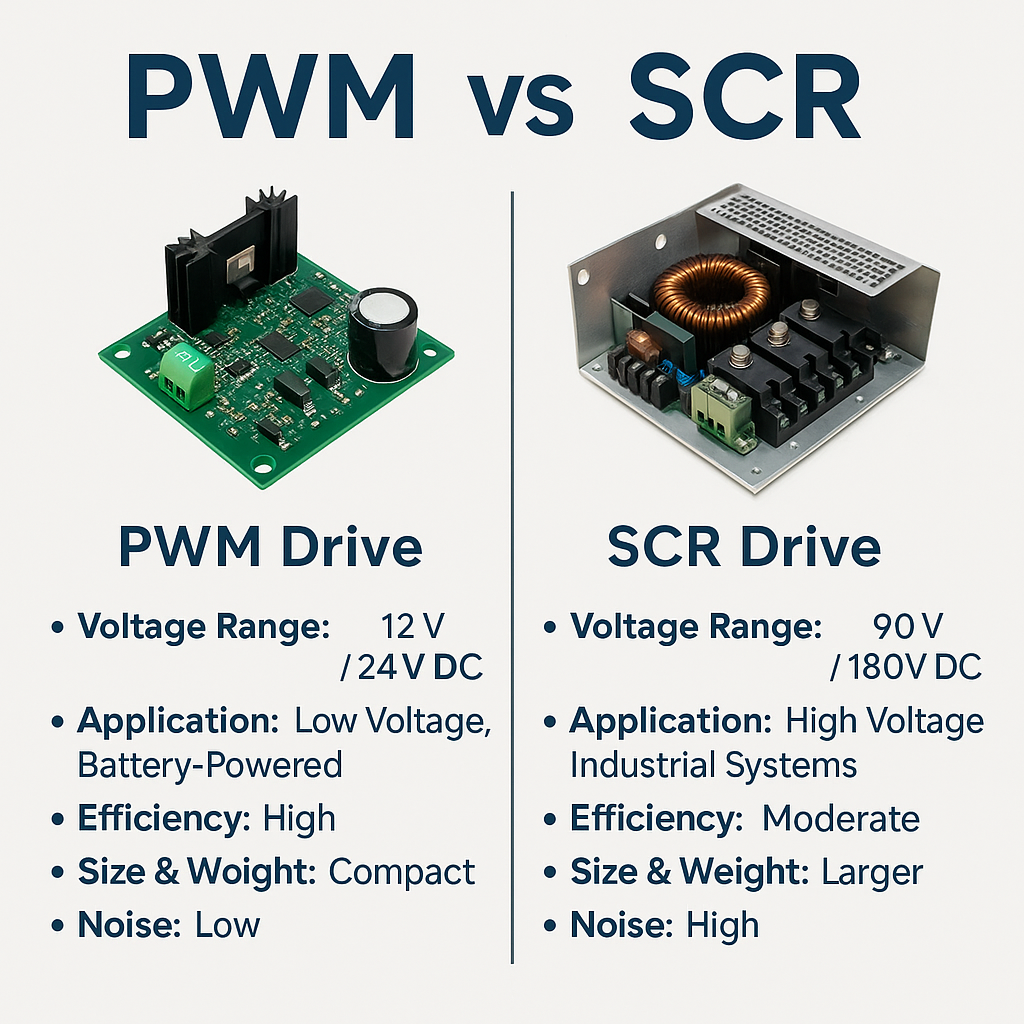

🛠️ PWM vs SCR Drive Comparison Table

| Feature | PWM Drive | SCR Drive |

|---|---|---|

| Voltage Range | 12V / 24V DC | 90V / 180V DC |

| Application | Low voltage, battery-powered | High voltage, industrial systems |

| Efficiency | High | Moderate |

| Size & Weight | Compact | Larger with heatsinks |

| Noise | Low (better motor response) | High (phase-angle control) |

| Regeneration | Not available (1Q drives) | Available (in 4Q models) |

| Ideal Use Cases | Conveyors, AGVs, robotics | Automation lines, test benches |

🚀 Which One Should You Choose?

At Ameronics, we recommend choosing the drive based on your application’s voltage, current requirements, and environment:

- Choose PWM Drives (like our FlexVolt Series) for:

- 12V / 24V systems

- Battery-powered or portable equipment

- Compact automation or robotics

- OEMs seeking efficient, low-noise controllers

- Choose SCR Drives (like our RedVolt or RegenCore Series) for:

- Industrial conveyor systems

- Test benches requiring regenerative braking

- High-current, high-duty-cycle applications

🔍 Still Not Sure Which Drive is Right? Let Ameronics Help

With over 15 years of experience in DC motor control, our engineering team at Ameronics can help you determine the best motor drive for your system. Whether you’re building a battery-powered solution or upgrading an industrial line, we offer both standard and custom drive controllers to meet your exact needs.

📩 Contact us today to speak with our experts or explore our product lines:

👉 www.ameronics.com

*This is AI generated image